PicoScope 7 Automotive

Available for Windows, Mac, and Linux, the next evolution of our diagnostic scope software is now available.

| Vehicle details: | Peugeot 406 |

| Year: | 2001 |

| Symptom: | Engine misfire |

| Author: | Nick Hibberd | Hibtech Auto-Electrical Diagnostics |

This was a 2001 Peugeot 406 2.0L petrol with a complaint of misfire, and it came with one of the most comprehensive shopping lists I’ve seen including: new plugs, new aftermarket coil pack, new genuine coil pack, new CKP sensor, replacement fuel pump, replacement fuel pump relay, replacement O2 sensor… and a partridge in a pear tree. The vehicle owner had a go at fixing it himself and the source of this wisdom came from online forums; god bless those forums. With a checklist of replacement parts already fitted, this should make it easier to diagnose. Wrong! Not only are you chasing someone else’s work, you are also having to deal with any problems inherited by interfering with those parts. You can only start at the beginning and fix as you find.

It was evident the misfire was fairly constant and didn’t seem dependent on engine load or temperature. A DTC check revealed a list as long as the replacement parts, none of which could be trusted based on the previous work so it was best to erase everything and start afresh. With the misfire present, the engine was run whist monitoring DTCs and live serial data. Each parameter seemed in line with normal values and there were no DTCs yet either. The PIDs worth mentioning were the HEGO predominantly hanging low and the fuel trims creeping up, which correlated with a misfire present and indicated unburnt oxygen entering the exhaust gas.

A power balance check isolated the problem cylinder to no.3 with the remaining cylinders pulling an even share of the running. A series of checks eliminated air flow, ignition and compression, which left only fuel delivery as the likely suspect. The next step was to verify the signal arriving at cylinder 3 injector.

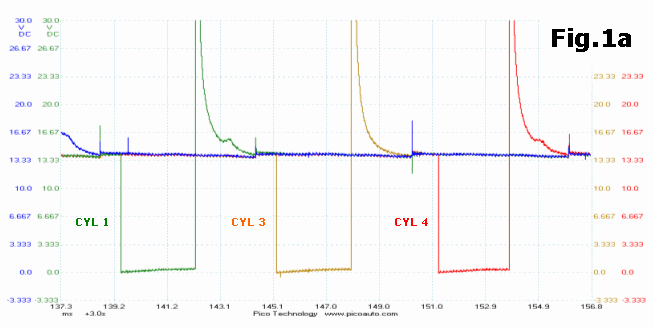

Fig.1 shows a collective view monitoring each negative pulse arriving at the 4 injectors. With any problem it’s best to collect as much information about the fault as possible. Viewing all of the injectors will help towards comparable analysis. At the moment this only represents signal voltage but it’s a good start. We are looking for something different associated to cylinder 3 injector operation. The checks include:

Analysing the capture already recorded in Fig.1 we can quickly run through some checks to eliminate possible causes.

Concentrating on our suspect cylinder 3 injector, the driver shows a clean switch to ground and the ground level itself is good. Injector pulse duration is in line with companion cylinders and the driver release is clean. Furthermore, the ground pulse was examined and gave a reasonable indication that the circuit integrity was good. This is backed up by the healthy inductive kick as the injector coil field collapses

Attention is drawn to the slight notch towards the end of the inductive kick. This notch occurs as the injector pintle moves through the collapsing field and finally closes. Notice that only cylinder 3 notch is missing. This is an indication that the pintle is sticking either shut or open. Since there was no excessive HC content from the tailpipe then the focus of the investigation now turned to the pintle sticking closed.

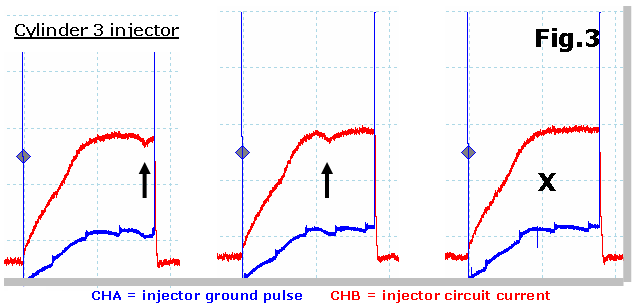

To further verify the fault, we need more information about circuit current. Where the voltage trace shows us when the pintle closed, it’s the current trace that shows us when the pintle opened.

Fig.2 is a typical recording captured from a known good injector on a neighbouring cylinder and clearly shows a repetitive and stable pattern surrounding pintle activity.

Fig.3 displays very different results showing the pintle fluctuating erratically and, worse, not opening at all. It follows that this delay in opening will significantly reduce the fuel quantity delivered to cylinder 3. The closed-loop fuelling is not cylinder-conscious: with the HEGO reporting a general lean condition, the ECM’s response is to add to the fuel trim until it sees the HEGO swing.

A new injector cured this complaint.

Surprisingly the customer took the final answer in disbelief: the four purring cylinders clearly weren’t enough. His testing eliminated the injectors early on by removing the rail and cranking the engine to see if the injectors spewed fuel, and they did, so he continued with the elimination process resulting in an expensive ghost hunt.

Having the ability to show before and after snapshots is a strong ally.

snock

July 02 2010

Very interesting. Scopes are the future of diagnostics. Continue sharing the experience.

Alan MacRobbie

March 22 2010

I appreciated this article—very good job. I had to chuckle at the comment—“God bless those forums” - I couldn’t agree more. Cheers!

Scott T

March 21 2010

Enjoyed your report Nick

Just wondering if you could elaberate on the check you did to eliminate ‘air flow’, ‘ignition’ and ‘compression’ - leaving only ‘fuel delivery’ as the likely suspect.

Regards

Scott

ray

March 21 2010

Excuse me but could a simpler test in logical sequence reveal the culprit?

a) comp test

b) test spark condition

c) s/plugs inspection and compare

find a method to determine which cyl is at fault ( can a Morse test be possible in this case? ) then switch over injectors and compre/ analize

obvious injector triggering to be tested too

those magical THREE cannot be separated

good compression good spark and adequate supply of fuel and in todays’ systems one has to make sure of the phasing of all three where neccesary tough this is not Diesel

last but not least has an actuation /injectors’ test been carried out by a scan tool actuation / simulation test? wonder what noise if any is noticed in a case where the pintle / nozzle is stuck?

cheers to all ray

gts mobile vehicle repairs

March 20 2010

Its a pity the common motorist doesn’t see whats involved with modern vehicle diagnostic process. I usually end up sorting other peoples and so called diagnostic experts. My PicoScope is invaluable. Thank you very much Pico.

Mac VandenBrink

March 20 2010

My compliments! very nice logical deduction.

Being an ignition proponent, I would have gone directly to ignition firing time analysis and not only found the misfiring cylinder, but also those who are not misfiring yet. This was obviously a dirty injector inhibiting proper pintle movement. If that was so, other injectors may follow sooner or later which can be seen on the scope pattern and a complete cleaning of the fuel rail would be preventive maintenance. It is a different approach and in no way meant to be critical.

Gary Smurthwaite

March 20 2010

Nice example Nick of showing how important the use of current analysis in diagnostic procedures.

Dave, your old formans comments are his opinion on most vehicle workshops. But we all know those who use oscilloscopes in our daily work cannot be classed as normal vehicle workshops. We are the future of modern diagnostics in my opinion, and those who won’t move forward will be left behind for sure.

ROGER JORDAN

March 15 2010

Excellent description as always Nick, thanks for taking the time and trouble to post the article, this certainly proves the need to measure current, voltage is not enough.

Kind regards Roger

Daniel

March 13 2010

Quote:“Surprisingly the customer took the final answer in disbelief…”

Don’t they all…! 😊)

I agree with Dave.

In ‘automotive repair terms’ a Good Scope makes the difference between a Doctor and Nurse!

Thanks Pico - keep evolving!

Dan

Dave Hill

March 05 2010

Nice one Nick!

It is good to hear of a real life example like this. I often scope injector volts/current & look for the “kink”, but so far I have never witnessed a sticky pintle. I am glad to hear that it is not a myth.

Examples like this go to prove the value of oscilloscope analysis. It surprises me just how many workshops don’t appreciate the need to get on board.

My old Foreman made a comment when we spoke last, he said “know one uses a scope these days!”

Yeah right!

“No scope = you won’t cope”

Keep the articles coming.

Regards

Dave