PicoScope 7 Automotive

Available for Windows, Mac, and Linux, the next evolution of our diagnostic scope software is now available.

Back-pinning Probe Set

Flexible Back-pinning Probe

Small Crocodile/Gator Clips

Premium Test Lead: BNC to 4 mm, 3 m

Premium Test Leads: Set of four leads 3 m (TA125 - TA128)

*At Pico we are always looking to improve our products. The tools used in this guided test may have been superseded and the products above are our latest versions used to diagnose the fault documented in this case study.

Plug a BNC test lead into Channel A of the oscilloscope. Place a small black clip on the lead end with a black moulding (negative) and a Back-pinning Probe onto the end with a red moulding (positive). Place the small black clip on to the motorcycle frame or battery negative, as illustrated in Figure 1. Check the manufacturer's pin data for the fuel injection Electronic Control Module (ECM) throttle position sensor connection terminal. Back-probe the correct multiplug pin with the Back-pinning Probe as in Figure 2. Ensure that a good connection is made through to the wire or terminal and the probe has pierced through the wire and plug insulation.

With the example waveform displayed on the screen you can now hit the space bar to start looking at live readings.

Note: this test was completed with the ignition on and without the engine running. The handlebar twist accelerator control was activated to the throttle stop and then released.

Figure 2

A good throttle potentiometer should show a small voltage at the throttle closed position, gradually rising in voltage as the throttle is opened and returning back to its initial voltage as the throttle is shut. Although many throttle position sensor voltages are manufacturer-specific, many are non-adjustable and the voltage is in the region of 0.5 to 1.0 volts at idle, rising to 4.0 volts (or more) with a fully opened throttle. For the full operational range, a time scale around 2 seconds is used.

The picture should be clean with no voltage 'drop out' at any particular point, as this small discrepancy will be sufficient to cause a 'flat spot' under initial acceleration.

This sensor or potentiometer has a linear output that indicates to the Electronic Control Module (ECM) the exact amount of throttle opening. It is used all in modern management systems. It is located on the throttle butterfly spindle, and is a 3-wire device usually having a 5 volt supply, an earth connection and a variable output from the centre pin. As the output is critical to the motorcycle's performance, any 'blind spots' within the internal carbon track's swept area will cause 'flat spots' and 'hesitations'. This lack of continuity can be seen on an oscilloscope and enables the operator to plot the output voltage over its operational range, showing any faulty areas.

The voltage seen on the oscilloscope should rise linearly with the amount of throttle opening. If there is an initial hesitancy, check and adjust the throttle cable or cables to within the manufacturer's specification. The picture must always be clean with no voltage 'drop out' at any particular point, as this small discrepancy will be sufficient to cause a 'flat spot' under initial acceleration. If this is the case, the throttle position sensor should be replaced.

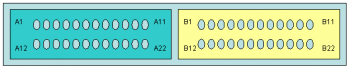

Our test vehicle was a Honda motorcycle. Below is the ECM multiplug pin data. Pin data will be manufacturer- and model-specific and this data is shown for illustration purposes only.

AT109-2

Disclaimer

This help topic is subject to changes without notification. The information within is carefully checked and considered to be correct. This information is an example of our investigations and findings and is not a definitive procedure.

Pico Technology accepts no responsibility for inaccuracies. Each vehicle may be different and require unique test

settings.

We know that our PicoScope users are clever and creative and we’d love to receive your ideas for improvement on this test. Click the Add comment button to leave your feedback.