PicoScope 7 Automotive

Available for Windows, Mac, and Linux, the next evolution of our diagnostic scope software is now available.

20 A / 60 A DC (low amps) current clamp

Small Delphi injector connector breakout lead

*At Pico we are always looking to improve our products. The tools used in this guided test may have been superseded and the products above are our latest versions used to diagnose the fault documented in this case study.

The purpose of this test is to check the actuation current within a Delphi-type Common Rail Diesel (CRD) solenoid injector circuit across a range of engine load and demand conditions.

WARNING

This test involves measuring a potentially hazardous voltage.

Please ensure you follow manufacturers' safety instructions and working practices and ensure the rated voltage for all accessories you are using meets or exceeds the expected voltage.

View connection guidance notes.

Note

The orientation of the amp clamp relative to the wire will determine whether it has a positive or negative output. If a live waveform does not appear on your screen, or appears to be inverted, try reversing the orientation of the clamp.

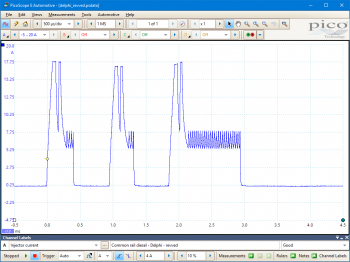

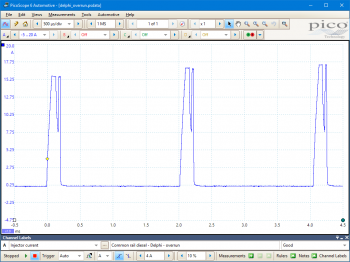

Engine at idle condition

Engine accelerated (increased demand) condition

Engine overrun condition

These known good waveforms have the following characteristics:

Note

Under some load and demand conditions, only one pilot injection might be observed (rather than two seen in the examples).

A common rail diesel injector delivers atomised fuel directly to the combustion chamber.

Injection timing and quantity is controlled by the Engine Control Module (ECM). Common rail diesel solenoid injectors can be actuated independently of the pressure generating mechanism, unlike their counterparts within distributor pump or unit injector (i.e. Pumpe-Düse or PD) systems, which can only operate within periods of high pumping pressure. This characteristic facilitates multiple injection events per engine cycle and permits additional functionality:

In order to facilitate their rapid operation, injector switching circuit voltages are quite high, typically 50 to 90 V.

Furthermore, the injector solenoids are rapidly energised using charge drawn from a combination of the vehicle power supply system and capacitors. The capacitors are charged by the circuit voltage induced by the solenoids when the supply voltage is removed.

Common rail diesel injectors are susceptible to mechanical and electrical faults, producing a variety of symptoms:

Selection of component related Diagnostic Trouble Codes (DTCs):

P0200 – Injector Circuit Malfunction

P0201 – Injector Circuit Malfunction – Cylinder 1

P0202 – Injector Circuit Malfunction – Cylinder 2

P0203 – Injector Circuit Malfunction – Cylinder 3

P0204 – Injector Circuit Malfunction – Cylinder 4

P0205 – Injector Circuit Malfunction – Cylinder 5

P0206 – Injector Circuit Malfunction – Cylinder 6

P0207 – Injector Circuit Malfunction – Cylinder 7

P0208 – Injector Circuit Malfunction – Cylinder 8

P0209 – Injector Circuit Malfunction – Cylinder 9

P0210 – Injector Circuit Malfunction – Cylinder 10

P0211 – Injector Circuit Malfunction – Cylinder 11

P0212 – Injector Circuit Malfunction – Cylinder 12

P0213 – Cold Start Injector 1 Malfunction

P0214 – Cold Start Injector 2 Malfunction

P0216 – Injection Timing Control Circuit Malfunction

P020A – Cylinder 1 Injection Timing

P020B – Cylinder 2 Injection Timing

P020C – Cylinder 3 Injection Timing

P020D – Cylinder 4 Injection Timing

P020E – Cylinder 5 Injection Timing

P020F – Cylinder 6 Injection Timing

P021A – Cylinder 7 Injection Timing

P021B – Cylinder 8 Injection Timing

P021C – Cylinder 9 Injection Timing

P021D – Cylinder 10 Injection Timing

P021E – Cylinder 11 Injection Timing

P021F – Cylinder 12 Injection Timing

P0261 – Cylinder 1 Injector Circuit Low

P0262 – Cylinder 1 Injector Circuit High

P0263 – Cylinder 1 Contribution/Balance Fault

P0264 – Cylinder 2 Injector Circuit Low

P0265 – Cylinder 2 Injector Circuit High

P0266 – Cylinder 2 Contribution/Balance Fault

P0267 – Cylinder 3 Injector Circuit Low

P0268 – Cylinder 3 Injector Circuit High

P0269 – Cylinder 3 Contribution/Balance Fault

P0270 – Cylinder 4 Injector Circuit Low

P0271 – Cylinder 4 Injector Circuit High

P0272 – Cylinder 4 Contribution/Balance Fault

P0273 – Cylinder 5 Injector Circuit Low

P0274 – Cylinder 5 Injector Circuit High

P0275 – Cylinder 5 Contribution/Balance Fault

P0276 – Cylinder 6 Injector Circuit Low

P0277 – Cylinder 6 Injector Circuit High

P0278 – Cylinder 6 Contribution/Balance Fault

P0279 – Cylinder 7 Injector Circuit Low

P0280 – Cylinder 7 Injector Circuit High

P0281 – Cylinder 7 Contribution/Balance Fault

P0282 – Cylinder 8 Injector Circuit Low

P0283 – Cylinder 8 Injector Circuit High

P0284 – Cylinder 8 Contribution/Balance Fault

P0285 – Cylinder 9 Injector Circuit Low

P0286 – Cylinder 9 Injector Circuit High

P0287 – Cylinder 9 Contribution/Balance Fault

P0288 – Cylinder 10 Injector Circuit Low

P0289 – Cylinder 10 Injector Circuit High

P0290 – Cylinder 10 Contribution/Balance Fault

P0291 – Cylinder 11 Injector Circuit Low

P0292 – Cylinder 11 Injector Circuit High

P0293 – Cylinder 11 Contribution/Balance Fault

P0294 – Cylinder 12 Injector Circuit Low

P0295 – Cylinder 12 Injector Circuit High

P0296 – Cylinder 12 Contribution/Balance Fault

GT099

Disclaimer

This help topic is subject to changes without notification. The information within is carefully checked and considered to be correct. This information is an example of our investigations and findings and is not a definitive procedure.

Pico Technology accepts no responsibility for inaccuracies. Each vehicle may be different and require unique test

settings.

We know that our PicoScope users are clever and creative and we’d love to receive your ideas for improvement on this test. Click the Add comment button to leave your feedback.

Ron Mcleod

April 09 2019

I like the example waveforms you include but I would like you to include a waveform of the injector on crank, I think it would be very helpful in a no start situation.