PicoScope 7 Automotive

Available for Windows, Mac, and Linux, the next evolution of our diagnostic scope software is now available.

| Vehicle details: | BMW M3 |

| Year: | 2003 |

| Symptom: | P1717 |

| Author: | Dave Hill | www.londonroadgarage.com |

Knowing when to say “No!” is something that we learn as we progress through the ranks in the motor repair business, but sometimes we still succumb to the urge to take on an interesting job. We recently had a 2003 BMW M3 drop in on us, with two warning lights displayed and the customer complaining that he kept losing his gears. This car is fitted with an SMG transmission and my knowledge was somewhat limited to be honest. I had read some horror stories, where owners had spent literally thousands of pounds before a fix was found. This really ought to be the job for a BMW dealership or independent specialist, but the masochistic side of me drew me into an interesting diagnostic process.

A global diagnostic scan pulled two significant fault codes. The DME (Digital Motor Electronics or Engine Management System to you and me) had the following DTC and definition… “Engine MIL on at request of SMG”. The SMG (Sequential Manual Gearbox) system had the following faults stored… “P1717 Hydraulic Motor On Time too long”.

This BMW SMG transmission is essentially a conventional manual gearbox, with an electrohydraulic control system, that has been developed using technology developed for the BMW/Williams Formula 1 car.

When considering the merits of taking on this kind of diagnosis, it is important to weigh up the customer as much as the vehicle. There is little point in proceeding if the owner is going to baulk at seemingly expensive and time consuming test and repair processes. If they are the sort that want the car by the weekend and have only a limited budget, then it’s time to walk away. The owner of this car was away in Abu Dhabi for several weeks and had expressed that he “Wanted it fixed!” and authorised a generous spend. Although he knew it could cost thousands to fix it, there was still considerable pressure on us to make sure that parts were not fitted unnecessarily.

Fortunately we have access to a tool with dealer level diagnostic capability and also an excellent technical information system, which is essential if an informed diagnosis is to be made. Control unit software versions were checked and found to be subject to newer version releases. This has become a big part of fault diagnosis in recent years. Faults can be logged due to over strict parameters which can be altered by system developers. In this case, both the engine and transmission controllers were brought up to date. Other system tests were carried out and the hydraulic pump relay was replaced (at the suggestion of the guided fault finding system). I had little faith in the relay being to blame for a prolonged pump run fault, but on the other hand, at only £10 (about US$16) for a component that is directly responsible for powering the pump, it didn’t seem unreasonable.

We ran the car for a week without a fault recurring and the owner’s brother in law came to collect. Typically ten minutes later, he returned with the exact same fault scenario. Intermittent faults will make the most professional repairer look inadequate! The car was left with us for more testing.

This time we tested and confirmed the accumulator residual pressure. This is done by an automated test plan performed on the diagnostic tool. The hydraulic system is vented and the residual pressure is displayed. We had 32 bar, where the minimum specified pressure is 29 bar. The pressure generation appeared to be reasonable too, taking approximately 20 seconds to build from 50 bar through to 70 bar (the system cycles between these two values).

It was fortunate that an identical car was available to us that we could take some good data readings from. This approach has often been pivotal when tackling complex and rarely seen faults and this time it would prove to be just as helpful. Initially only basic comparisons were made, i.e. pressure generation and decay times were compared in “live data” using a stop watch. This didn’t really show anything conclusive, so a new approach was required. There is only one way to study the pump functionality in minute detail and that is with the scope. By capturing the hydraulic pump current signal, during its operation from zero through to 80 bar and comparing to the same capture from the known good car, it was hoped that some conclusive information could be found.

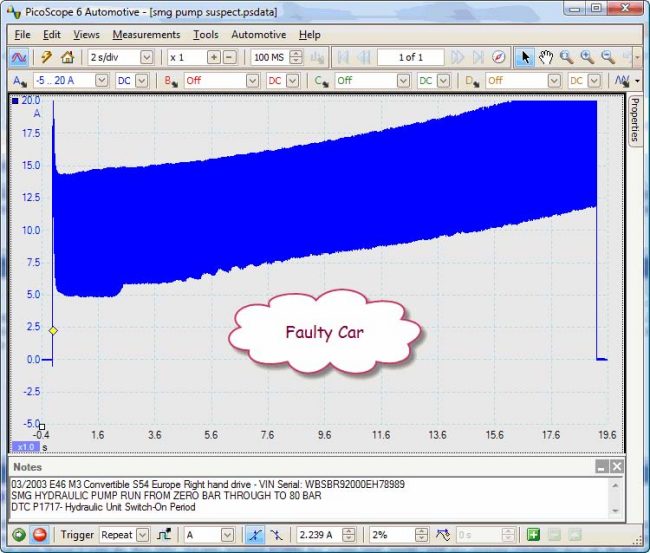

Here is a capture taken of the hydraulic pump current draw. Taken over a 20 seconds (total screen time) and with a 20 amp vertical scale.

Figure 1: The faulty car

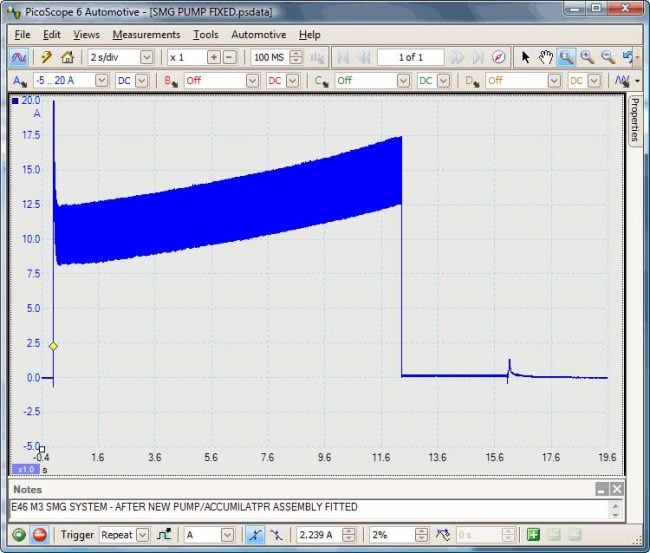

Figure 2: The good car

Looking at the two captures, it is instantly obvious that there are a couple of differences. Firstly the time taken to generate the 80 bar value (pressure values were reported on the scan tool) can be seen to be approximately 8 seconds quicker on the good car. Secondly, the vertical scale of the capture appears to be quite “noisy” on the faulty car capture. Look at the narrower signal (Figure 2) on the good car. This could be a fault and we really need to zoom in and understand what is happening here.

Before we zoom in, it should be highlighted that it is important to make sure that when comparing values from two vehicles, the test conditions are as close as possible in each instance. Both cars had been left for several hours, so that the pressures had decayed to zero and just as importantly, the temperature of the hydraulic fluid had settled to an ambient level. This is important as it would be pointless trying to compare pressure development times if one car had hot fluid and the other had cold. The viscosity of the fluid will likely influence the pump’s ability to develop pressure, but also it will affect the time it takes the fluid to leak or decay away past the numerous actuators, valves and solenoids.

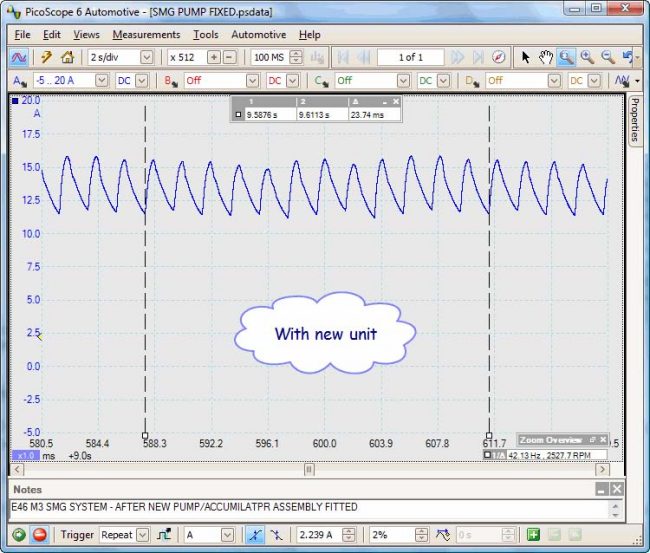

OK now for closer inspection, with the same capture as before, but this time zoomed in 512 times (horizontally)…

Figure 3: Faulty car zoomed

Figure 4: Good car zoomed

In the two previous captures, we have zoomed in (X 532) to the point where we can see the individual current events associated with each segment on the pump motor commutator ring. In the close up of the poorly car (Figure 3) we can see a curious signature that is repeated in each rotation and also a repetitive cycling of the overall current draw. Compared to the consistent signal from the good car (Figure 4), we can see that we have an issue.

Initially it was not clear whether the undulations in the overall current were a result of a problem with the pump/motor assembly itself, or perhaps due to fault elsewhere in the hydraulic system. Perhaps a poor seat on a valve might cause an uneven load on the pump motor and this might cause the irregular current curve? Whatever, this assembly costs nearly £1700 (about US$2700) and guesswork is not an option.

There is one important clue to be seen within the capture from the faulty car. You will notice the commutator segment signal with the flat bottom. This signature pattern is repeated over and over throughout the whole waveform and in each instance it is in the same dip in the cycling current. This is important, because it ties the rise and fall in current undisputedly to the rotational position of the pump motor. It suggests that the rise and fall in current draw is caused by an issue local to the pump motor or pump itself.

With this new information, the new part was ordered and after fitting and bleeding the system, a repeat capture was made, so that the repair could be confirmed. As you can see, the system now resembles that of the known good car.

Figure 5: Repaired car

Figure 6: Repaired car zoomed

Conclusive I think!

The car has been with the customer for a while now and he has emailed me to express his gratitude. It now drives very differently to the troublesome car that was presented to us and some of that should be attributed to the latest software that we loaded.

This is another example of why scope use is essential in the job today. The evidence is obvious and the final proof of repair is important. The parts alone associated with this repair cost £1470 (about US$2300) + VAT. This is not the sort of arena to be practising in “best guess” diagnostics and again PicoScope has played a fundamental role in the process of doing the job properly. I don’t see that I would have ordered the parts, without the information gained from the scope evaluation and I wonder if the dealers go in this deep?

After owning PicoScope for just four years and with no previous oscilloscope experience, the benefits of ownership are clear to see. The way that signals can be captured over very long time bases and then manipulated so that the fine detail can be studied is fantastic. If you want to step up to the challenge of the modern job and gain an advantage, it really is a “no brainer!”

Magnus Östlund

July 31 2018

Have same problem and read the article byt don´t understand what the solution is 😊 Best regards Magnus

Andreas Erikson

May 08 2018

Hi and thanks for a great article! I have the exact same fault, P1717 in ODB reader, but BMW’s own checks shows all green in the SMG system. However the yellow kugwheel on the dash warning for SMG problems turns on and the car looses gears from time to time (e.g. when standing still at a red light). Was the solution to change the commutator or the whole pump? I didn’t understand that even though I have read it several times =). Was the commutator possible to buy from BMW? Many thanks! BR Andreas

Jim McHardy

January 17 2014

Very interesting article, I have just bought an E46 convertible and will meet up with it when I return to the UK later in February, I test drove the car 2 weeks ago and have traded in my well trusted and loved Z4 for it. I am aware of this type of system as it is used in another application in Heavy Mobile cranes (albeit a great deal bigger scale) but the function and control is very similar.

Steve Evans

July 07 2012

See http://www.m3forum.net/m3forum/showthread.php?p=1065614466 for a picture of a worn SMG pump motor. My car is reporting the exact same error codes. My motor is being rewound as I type!

DOMENIC

January 19 2012

Yes the thrill of diagnostics can be a bit of a bug in its self as a Main dealer technical expert and workshop foreman in at the deep end i know the feeling well. a very interesting article.

Tim

August 03 2011

There should be more mechanics like you, especially in US. I have my car currently in the shop and the dealer is giving me different stories everyday. That’s how i ran into this site by trying to do my own research. Keep up the good work..

NICU BIGHIU

March 08 2011

Nice work,congratulations!

phil j

March 07 2011

makes you wonder what the dealer would do?

do they have known good waveforms to compare or would they do the same as Dave and take comparison off a good one.

there’s no disputing the poor commutator pattern though, that’s the same for any dc motor.

nice one Dave!

Darren Cotton

March 05 2011

Well done Dave - excellent case study. To all those that take the time to do a case study, very well done. I also find these educational, not to try and find faults with the detail, but to see what I can I benefit from the study. Thanks to Dave and all those that do these.

malama

March 03 2011

I wanted to find out if the pump is repairable, because it sounds expensive to replace the pump with a new one especially when you live in the sub-Sahara because our workshops do not spares so need order.

Aaron Firth

March 01 2011

God amazing detail really well done. I dont know what i find more amazing the lengths you have gone to or the fact you have found the time to do it, I dream of having the time to “play” with something like this the reality of a modern garage is time is money and the money I can make on the less intricate problems far out weighs what I can charge on something like the above. Sadly customers believe all diagnostics should only cost £50 and the customer will only judge you on the cost of replacing a pump they just won’t see the blood sweat and tears that have gone into a job like this.

But again well done on a fantastic piece of detective work.

Aaron ARN Diagnostics Doncaster

Gary

March 01 2011

I’d just like to say that the time and effort applied in putting this type of informative piece together Dave is always greatly appreciated by myself - and others within the organisation I work within (a major motor manufacturer), who also read your diagnostic pieces.

Please do not feel that you’re efforts are not appreciated. As others have already said - keep up the EXCELLENT work Dave - every day’s a school day! And maybe these people are so clever they know it all - I wonder if that’s why they fail, and you succeed!

Kind regards

solly

February 28 2011

well done, Dave.we all know how extremely difficult it is to juggle the day to day running of workshop commitments,and to actually find a few spare moments to put together a meaningful thesis is exemplary.yes we do need a broad database of wave form library,with comprehensive model and variety of possible known fixes.keep up the good work.

colin

February 28 2011

nice work and a good answer,i use the pico quite regular but having the gonads to post my own case study is more scary than using the scope,keep up your good work and i love reading your case studies.well done and another feather in your cap.

Dave Hill

February 27 2011

Wow this one is attracting some feedback!

Thank you all for the comments, but what do you want from me….......... blood? 😊

Yeah OK I have not amended the notes on the other waveform & yes I could have supplied an image of the stripped pump & motor, to show the commutator. Truth is, I did these things & more, but I have to condense it all into a passage of text that is suitable for publishing. The fact is fellas, that I am trying to run an everyday workshop & my time is stretched in many directions. However, I take on board everyone’s comments & I will try to improve my efforts.

For those of you who are interested, here is a link to both psdata files: [files removed as they were broken links: 10-01-2023]

Here’s a thought gentlemen…. There is one thing that you can all do to improve the experiences of each of us & that is to contribute a piece of your own work as a case study.

Thanks again for the responses

Ferdinand

February 27 2011

Very good job dave.

Jon Morgan

February 27 2011

The diagnosis was well thought out & confirmed with the use of a Known good comparison.

Had there been no comparison, how would you have proceeded? Would the testing have continued or would you have been confident enough to order a new pump based on the dropout on the commutator?

A comprehensive good & bad waveform library looks essential using this diagnostic approach as an example.

Keep up the good work Dave, as a new Pico user I find these case studies incredibly useful.

All the contibutors who take the time to put case studies together on here are deserving of a round of applause.

Stuart D

February 27 2011

Brits comments are spot on. The biggest problem is having a good waveform or a bad one for that matter to do comparisons on. The article is very well presented and the diagnostic approach good. The key factor in the decision to but the expensive pump was the bad scope waveform, but only because you had a waveform to compare against. Although the diagnosis was right and the final outcome satisfactory, would you have bought a pump had you not had a similiar car to compare against?? A good and bad waveform library is a must. Come on PICO ! LETS GET IT ROLLING !!

eric

February 26 2011

I suspect the dealer would have simply thrown a pump on it and hoped for the best.

Brit

February 26 2011

I think the importance of promoting that people send in wave forms from normal cars is paramount here. We need to build a huge library of waveforms. Having the luxury of the same vehicle is not commonplace.

Dr. Jake Payne

February 26 2011

A picture of communtator would have been nice. To see why you are getting that pattern would aid in understanding the pattern shown. The code itself leads one to think that the pump motor is not up to par as per it’s own self testing. Using another car for comparison is always an excellent idea. You can get real useful information that way not likely to be a book. Good job on it, sir.

Kenny Duke

February 26 2011

The pattern from the good car zoomed compared to the repaired car zoomed looks like the good car will have problems soon.

David Paterson

February 26 2011

I love the English “Deckchair” humour!

Despite the ‘foreplay’ of the article taking a while, the detail of the the images demonstrates the immense capacity of the Picoscope and why without a really powerful scope, such events would be missed. Ian Taylor has a point, in that the same VIN number does change things a little, but this doesn’t really matter - we now all have another pair of good and bad examples to add to own waveform libraries.

What the article does show is that if you aren’t 100% sure of the need to change such an expensive item, you are under pressure to find that identical car, if you don’t know what the waveform should look like. In this case, the repeative signature which is only seen by being able to zoom in to such an extent, gives that conclusive evidence of this type of fault. Nonetheless, again, an interesting and thought-provoking article. Thanks, Dave!

Simon Rowe

February 26 2011

The reference trace taken from the good working car is quite different from the faulty car with it’s new pump. I wonder if that is typical of a nicely bedded set of brushes? Did you open the old pump for a visual inspection?

Ian Taylor

February 26 2011

Very interesting article, but why are the vin numbers the same on the good car and the bad? Suspect someone forgot to change the notes!

Deckchair5

February 25 2011

Are you saying we have to buy an identical good car in order to make comparisons to confirm our suspicions? Why not give the owner the identical good car? :~)

David Chiffens

February 25 2011

You are a brave man to take this one on. But I know the feeling of the challenge. Its somethiing us auto techs get with that “its been to every other shop and no one can fix it” Now its your turn.

shane

February 25 2011

an excellent approach for diagnosing that vehicle