PicoScope 7 Automotive

Available for Windows, Mac, and Linux, the next evolution of our diagnostic scope software is now available.

Back-pinning Probe Set

Flexible Back-pinning Probe

PicoScope Sprung Hook Probe

Small Crocodile/Gator Clips

Premium Test Lead: BNC to 4 mm, 3 m

Premium Test Leads: Set of four leads 3 m (TA125 - TA128)

*At Pico we are always looking to improve our products. The tools used in this guided test may have been superseded and the products above are our latest versions used to diagnose the fault documented in this case study.

Plug a BNC test lead in to Channel A of the scope. Place a small black clip on the lead end with a black moulding (negative) and a Back-pinning Probe onto the end with a red moulding (positive). Place the small black clip on to the motorcycle frame or battery negative, as in Figure 1. Check the manufacturer's pin data for the fuel injection Electronic Control Module (ECM) lambda sensor connection terminal. Back-probe the correct multiplug pin with the acupuncture probe as in Figure 2. Ensure that a good connection is made through to the wire or terminal and the probe has pierced through the wire and plug insulation.

With the example waveform displayed on the screen you can now hit the space bar to start looking at live readings.

The sensors have varying electrical connections and may have up to four wires; they react to the Oxygen content in the exhaust system and produce a small voltage depending on the air/fuel mixture seen at the time.

The voltage range varies, in most cases, between 0.2 and 0.8 volts: 0.2 volts indicates a lean mixture and a voltage of 0.8 V shows a richer mixture.

Lambda sensors can have a heater element to assist the sensor to reach its optimum operating temperature. Zirconia sensors when working correctly switch approximately once per second (1 Hz) and only start to switch when at normal operating temperature. This switching can be seen on the oscilloscope, and the waveform should look similar to the example. If the frequency of the switching is lower than anticipated, remove the sensor and clean with a solvent spray and this may improve the response time.

The lambda sensor is also referred to as an Oxygen (O2) sensor or a Heated Exhaust Gas Oxygen (HEGO) sensor, and plays a very important role in control of exhaust emissions on a catalytic-equipped vehicle. The lambda sensor is fitted into the exhaust pipe before the catalytic converter. Vehicles compliant with EOBD2 legislation also have a post-cat lambda sensor.

A vehicle equipped with a lambda sensor is said to have 'closed loop' control. This means that after the fuel has been burnt during the combustion process, the sensor analyses the resultant emissions and readjusts the engine's fuelling accordingly.

The lambda sensor is essentially two porous platinum electrodes. The outer electrode surface is exposed to the exhaust gases and is coated in a porous ceramic with the inner coated surface exposed to fresh air.

The most commonly used sensor uses a Zirconia ceramic element, producing a voltage when a difference in oxygen content is seen between the two electrodes. This signal is then sent to the Electronic Control Module (ECM) and the mixture is adjusted accordingly.

Titania is also used in the manufacture of another type of lambda sensor which offers a faster switching time than the more common Zirconia sensor.

The Titania Oxygen sensor differs from the Zirconia sensor in that it cannot produce its own output voltage and is therefore reliant upon a 5 volt supply from the vehicle's ECM. The reference voltage is altered according to the engines air-fuel ratio, with a lean mixture returning a voltage as low as 0.4 volts and a rich mixture producing a voltage in the region of 4.0 volts.

An ECM only controls the fuelling in 'closed loop' when the appropriate conditions allow, normally during idle, light load and cruise operations. When the motorcycle accelerates, the ECM allows overfuelling and ignores the lambda signals. This is also the case for initial engine warm-up.

Both Titania and Zirconia sensors when working correctly switch approximately once per second (1 Hz) and both only start to switch once the normal operating temperature has been achieved. This switching can be observed on an oscilloscope or by using the low voltage range on a multimeter. When using an oscilloscope, the resultant waveform should look as the illustration above. If the frequency of the switching is slower than anticipated, the removal of the sensor and cleaning with a solvent spray may improve the response time.

A constant high voltage output from the Zirconia sensor shows that the engine is running constantly rich and is outside the ECM's adjusting range; whereas a low voltage indicates a lean or weak mixture.

If the frequency of the switching is slower than anticipated, remove the sensor and clean with a solvent spray and this may improve the response time.

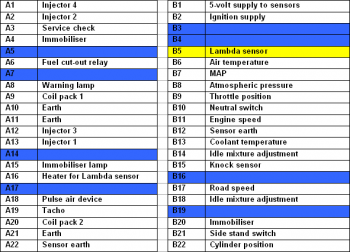

Our test vehicle was a Honda motorbike. Below is the ECM multiplug pin data. Pin data is manufacturer- and model-specific and this data is shown for illustration purposes only.

AT111-2

Disclaimer

This help topic is subject to changes without notification. The information within is carefully checked and considered to be correct. This information is an example of our investigations and findings and is not a definitive procedure.

Pico Technology accepts no responsibility for inaccuracies. Each vehicle may be different and require unique test

settings.

We know that our PicoScope users are clever and creative and we’d love to receive your ideas for improvement on this test. Click the Add comment button to leave your feedback.